prototyping and production, customer adaptation solution

2010 – 2022

In 2010, my company was invited to cooperate with the VOLVO POLAND bus factory in Wrocław. The factory‘s representatives were looking for a supplier who could undertake the production / delivery of parts in carbon & carbon look technology. Since we made such parts for our automotive car audio projects, we were recommended by one of the employees of the factory department as a suitable partner. For Volvo, we produced exterior elements for the top Volvo Coach 9900 bus model. Due to this cooperation, my company changed into ECA GROUP.

In 2011, in response to the demand signaled by the factory, I designed innovative body decorative strips for the new Coach 9900 bus model. I used aluminum instead of stainless steel and fastening with 3M double-sided tape instead of gluing. Moldings were installed along the entire body on the lower window line. Prototype elements were presented to the factory’s customers and the general public during the BUS WORLD trade fair in Kortrijk / Belgium in the same year. After a very positive reception, a decision was made to award my company a contract for the production, delivery and assembly of the above-mentioned moldings on the new bus model. I implemented and launched the production of these elements in the company, coordinated their delivery and was directly responsible for the assembly of moldings on the bus body on the production line at the Volvo factory in Wrocław. In total, we have delivered and installed over 360 sets of strips without any quality complaints from either the factory or the market / customers!

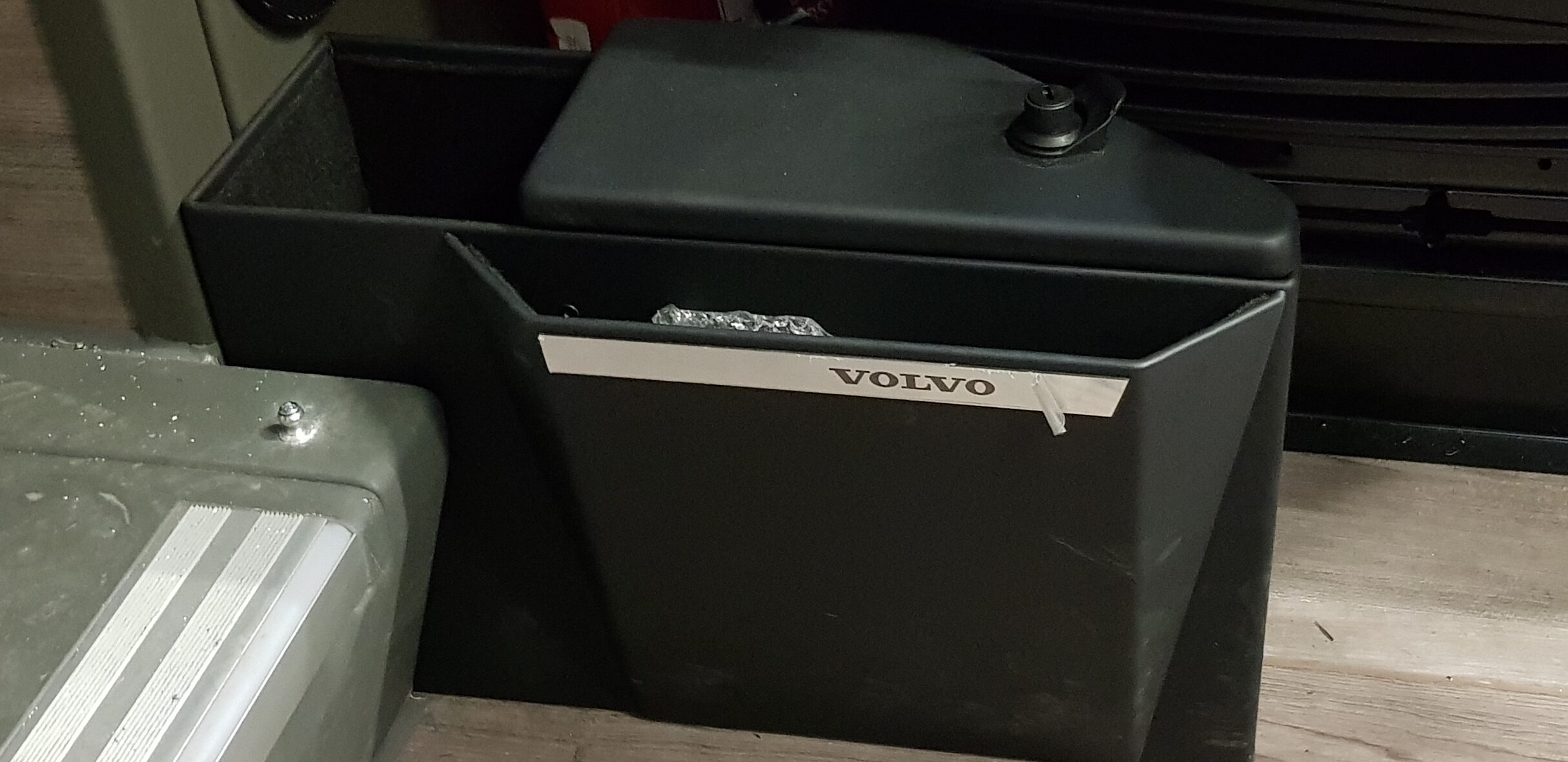

In 2014, upon a request from the factory, I designed LCD screens / housings and driver storage inside the bus. After the enthusiastic acceptance of the prototypes, I implemented and launched the production of these elements in my company. The elements were made of aluminum and trimmed with ecological leather. In the meantime, I was designing and executing, in my company, numerous atypical custom orders placed at the factory by its customers – in the so-called customer adaptation solution formula. The following should be mentioned among the most important standing CA orders: trim of steering wheels, special finish in natural leather of overhead ventilation tunnel covers, In 2018, with the new Volvo Coach 9900 bus model, I started designing a new version of a set of decorative strips according to a new design delivered from the factory. At the same time, from the beginning of 2019, I was negotiating a new contract for the production and delivery of these elements. Unfortunately, the C19 pandemic has stopped the bus business, and we have only been getting new CA orders from this industry for a few months …

Below are some photos related to this activity